Vol.1|"Carefully dealing with heat-sensitive materials"

Facing Heat-Sensitive Materials with Care

- The difficulty of polylactic acid dyeing and the days of research. -

Dyeing is a delicate process that involves not only applying color, but also interacting with the individuality of the material.

The polylactic acid material used for ENSULO products has environmentally friendly characteristics, but it is also susceptible to heat and alkali, requiring different considerations from general dyeing.

"This material has to be dyed only once. It cannot be redone,” says a technician who has worked with dyeing for many years at a dyeing factory.

In fact, there have been unexpected problems such as fabrics being cut due to excessive heat or re-dyeing, or colors evaporating and losing colorfastness.

Despite these failures, “We found just the right conditions by understanding the characteristics of each material one by one and conducting repeated tests.

As if talking to the materials, we repeatedly checked and adjusted the dyeing process to expand the possibilities of dyeing.

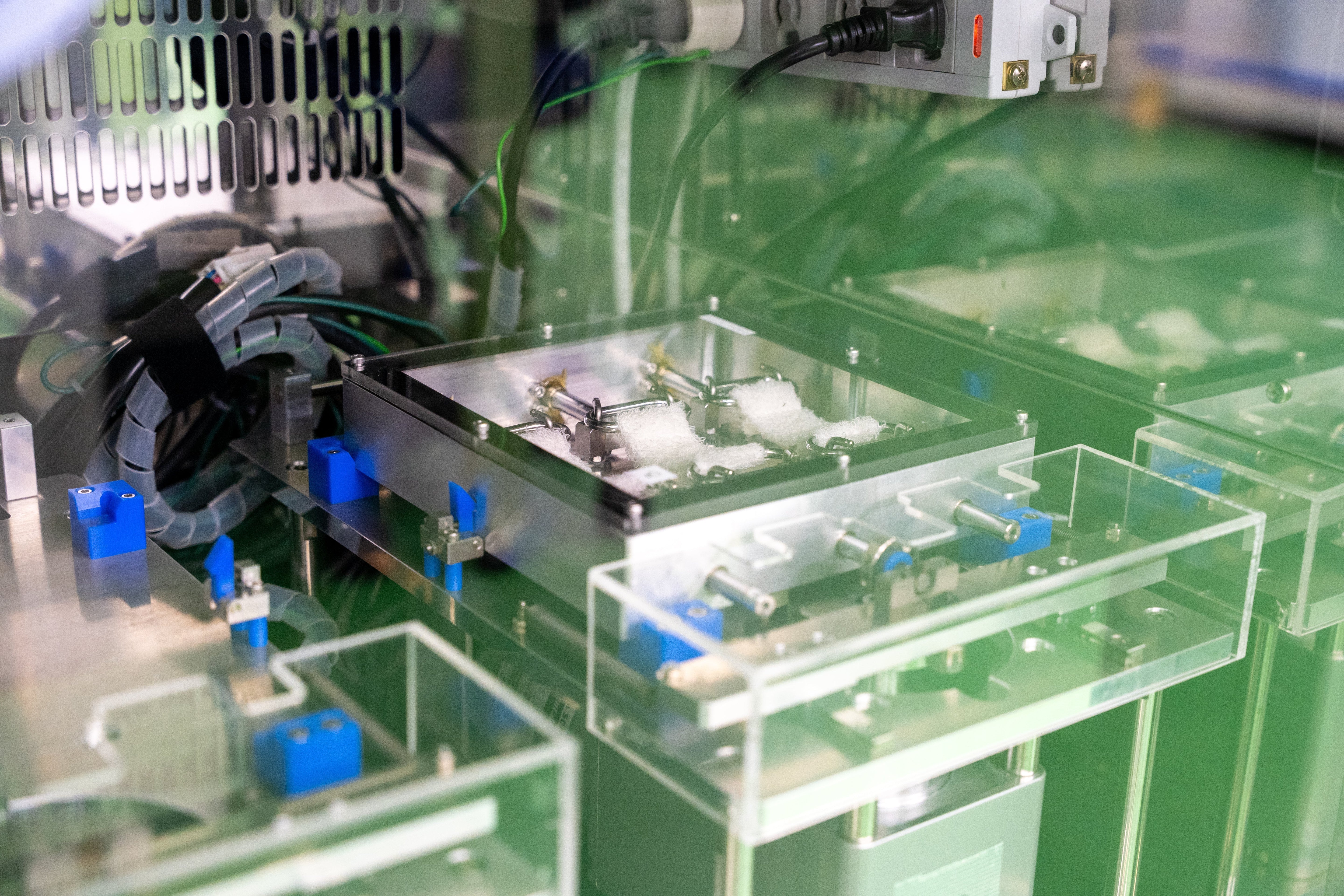

In particular, in the drying process, instead of using the conventional method of finishing at high temperatures for a short time, they used a tenter machine that is three times as long as the conventional method, and used a low temperature and slow finishing method.

How can we finish the process beautifully without damaging the material?

This thought was carefully incorporated into every detail of the dyeing process.

The challenge of using new materials is also an opportunity to rethink the very nature of dyeing.

The idea of “not overworking” is also to reduce complexity and to take advantage of the original texture of the material.

While reducing the number of hands, quality is not compromised.

This is supported by the experience and intuition of our craftsmen.